How To Avoid Distribution System Failure And Breakdown Through Thermal Imaging?

IMPORTANCE OF REGULAR ASSESSMENTS FOR ELECTRICAL RELIABILITY

In cases where electrical connections and components unexpectedly malfunction, the repercussions can encompass unscheduled periods of inactivity, incurring substantial expenses for repairs, and enduring production setbacks. Additionally, the likelihood of fire incidents escalates due to occurrences such as electrical short-circuits or the combustion of cables.

Consequently, prioritizing regular assessments becomes imperative to confirm the optimal functionality of the electrical distribution system. This encompasses meticulous examinations of vital elements like busbars, circuit breakers, fuses, and switchboards. These electrical distribution panels are usually ensconced within enclosures, which complicates the process of scrutinizing them for potential malfunctions.

PROPOSAL FOR PROACTIVE MAINTENANCE

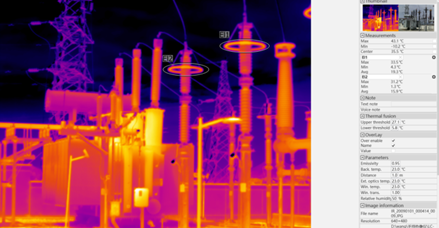

Normally, electrical connections and components exhibit signs of excessive heat prior to experiencing failure. Thermal imaging technology offers a valuable perspective that surpasses the capabilities of human vision alone. A thermal camera, exemplified by the FLIR E95, is capable of revealing areas of elevated temperature on components and connections. This aids maintenance experts in identifying areas of strain within an electrical setup, anticipating potential breakdowns before they occur.

Employing thermal imaging equips professionals with the means to preemptively address electrical anomalies through scheduled maintenance, preventing the emergence of severe and costly issues. By integrating thermal imaging with tools like damp meters, digital multimeters, and IR Windows, maintenance professionals can comprehensively assess the operational efficiency of the distribution system.

POSITIVE OUTCOME AND RESULTS

By conducting routine thermal inspections, maintenance experts can swiftly identify and pinpoint temperature irregularities, commonly known as hot spots, within electrical equipment and components. A thermal imager proves invaluable in detecting concerns such as loose connections, poor contacts, fuse problems, imbalanced loads, and stressed earth leakage scenarios.

The adoption of thermal imaging significantly enhances safety measures by mitigating the potential for electrical fires. This practice also aids in circumventing unforeseen equipment failures and subsequently minimizes the risk of unanticipated electrical disruptions. Furthermore, it facilitates the proactive organization of planned repairs and preventive maintenance initiatives, thus contributing to the overall reliability and efficiency of the electrical system. For more information, you can also refer to our case study of successful deployments here.