Enhancing Plant Safety Through Optical Gas Imaging

In the role of a plant safety manager, the primary concern is safeguarding personnel and the environment. Effectively managing risks necessitates accurate insights into potential hazards, and this is where safety equipment plays a pivotal role. Among our solutions to protect the environment from the potential dangers such as hazardous gases, optical gas imaging (OGI) stands out. This advanced imaging solution has the potential to revolutionize the detection and mitigation of gas leaks in industrial settings, thereby significantly enhancing plant safety protocols.

The Imperative for Enhanced Safety Measures

Across industrial plants, the presence of volatile organic compound (VOC) gases presents substantial risks to human health and the environment. Gas leaks not only result in operational losses but also pose a fundamental safety hazard. Gases like methane and natural gas are particularly concerning due to their flammable and explosive properties. Additionally, such leaks can lead to long-term health problems and contribute to environmental challenges like climate change and wildlife endangerment. The dual nature of these threats – physical harm and reputational damage – underscores the urgency of effective leak detection and management strategies.

Identifying Culprits: Understanding Gas Leak Origins

Effectively addressing gas leaks necessitates understanding their root causes. Leaks can stem from various sources, including aging equipment, insufficient maintenance, and improper installations. Given the intricate network of flanges, unions, and connections within industrial plants, completely eradicating leaks is a formidable task. Hence, the prompt identification and resolution of leaks become paramount to avert potentially catastrophic outcomes.

Optical Gas Imaging (OGI) to the Rescue

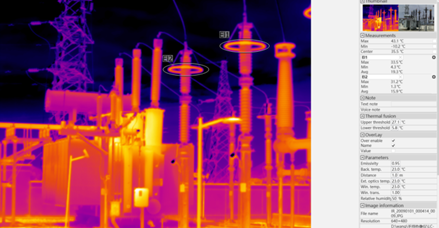

Optical Gas Imaging (OGI) technology offers a revolutionary solution by rendering otherwise invisible gas leaks visible. By utilizing an infrared camera equipped with a specialized filter, OGI can detect an array of hydrocarbon gases. Noteworthy gases identified by OGI include methane, benzene, butane, ammonia, and sulfur dioxide. This technology serves as a robust tool for real-time gas leak monitoring, empowering safety managers to promptly identify potential hazard zones.

Exploring Variants of OGI Cameras Diverse types of OGI cameras cater to varying plant needs, providing adaptability and precision in leak detection.

Fixed Mounted Cameras For scenarios necessitating continuous surveillance, fixed mounted OGI cameras excel. They offer a dependable solution for tracking leakage points in specific areas or equipment. Refinery processing units, volatile chambers, and flare towers are among the settings benefiting from fixed cameras, which provide live data for comprehensive risk management strategies.

Remote Infrared Systems For plants spanning extensive areas, remote infrared cameras prove invaluable. Operable from the ground or affixed to aerial platforms like drones, helicopters, or planes, these cameras boast an impressive range of up to 1.5 miles. They are particularly advantageous for surveying vast landscapes or accessing hard-to-reach spots.

Handheld Cameras Handheld OGI cameras are indispensable for daily monitoring, inspections, and risk evaluation. These cameras divulge leak locations and causes, enabling accurate reporting and documentation. With built-in WiFi capabilities, captured data can be instantly shared with teams for swift decision-making.

In conclusion, the advent of optical gas imaging is assisting the approach of plant safety managers towards gas leak detection and risk mitigation. By providing real-time visualization of gas leaks imperceptible to the naked eye, OGI empowers safety teams to take immediate action and prevent potential disasters. Whether through handheld, remote, or fixed cameras, OGI offers versatile tools tailored to the distinctive needs of diverse industries. Embracing such cutting-edge technologies will undoubtedly contribute to safer and more sustainable industrial practices as we progress ahead.