Germanium Lenses Overview

Similar to conventional photography cameras, numerous thermal cameras feature compatibility with interchangeable lenses. This adaptability allows a single tool to effectively transform into multiple instruments, offering the versatility to attach various additional lenses such as macro, telephoto, or wide-angle options.

The selection of the lens is contingent upon the specific scanning context and requirements. This functionality empowers users to tailor their thermal imaging equipment to the precise needs of each situation, thereby enhancing the camera's capabilities and ensuring optimal results.

What is a thermal camera lens made of?

Thermal camera lenses are commonly crafted from germanium due to the material's exceptional attributes within the Infrared spectrum. Germanium, an element present on the periodic table and found naturally, possesses distinct properties related to infrared optics. Its qualities of transmission and Index of Refraction in the infrared spectrum make it an ideal choice for infrared optics applications.

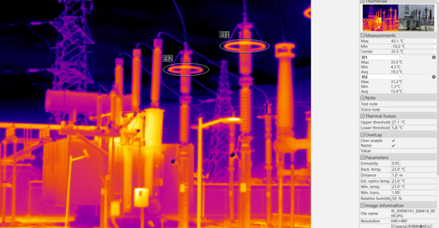

While germanium is opaque to the naked eye, it remarkably exhibits high transparency to infrared radiation, particularly within the 8-14 micrometer range. This unique feature makes germanium glass a favored material for crafting lenses that enable thermal cameras to effectively capture and interpret infrared emissions.

Germanium Camera Lens

Just as conventional visible light camera lenses are crafted from solid glass, thermal camera lenses are solid pieces made from germanium. This similarity stems from the fact that, much like glass's transparency to visible light, Germanium boasts transparency to the specific wavelength range of infrared radiation that most thermal cameras utilize.

In both cases, the application of anti-reflective coatings can significantly enhance performance by reducing the loss of light and energy caused by reflections on the lens surfaces. This holds true for both visible light camera lenses and infrared (IR) camera lenses.

When germanium is coupled with a meticulously engineered anti-reflective coating, it transforms into an exceptionally efficient material for transmitting energy to the thermal camera's detector, thereby producing high-quality thermal images. Moreover, this coating is designed with durability in mind, enhancing scratch resistance and ensuring robust performance even in demanding environments.

Types of IR lenses

Each lens type has specific characteristics that make it suitable for particular scenarios. Here's a brief overview of different lens types and their applications:

1. Wide-Angle Lens

Utilizing a wide-angle lens significantly broadens the field of view of your thermal camera. This lens type becomes indispensable when the goal is to capture a larger portion of the surroundings surrounding an asset or when operating within confined spaces. Wide-angle lenses prove essential for capturing comprehensive images in scenarios where an extensive view is crucial.

Home inspectors, for instance, benefit greatly from wide-angle lenses when assessing the exterior of a house. These lenses enable inspectors to encompass the maximum area within a single frame, enhancing efficiency and facilitating a comprehensive assessment of the property's exterior.

2. Standard Lens

Conducting a comprehensive assessment of the electrical equipment situated throughout the factory involves capturing images and observing components in proximity. In situations where you're examining equipment at close distances and from eye-level positions, opting for the standard lens is advisable.

3. Telephoto Lens

When you're tasked with scanning a sizable area situated at a greater distance, such as the ceiling or roof of a factory or warehouse, the utilization of a telephoto lens becomes essential. Opting for a telephoto lens with 2x or 4x zoom capabilities typically offers sufficient magnification to observe the required details from a distance. This lens type proves advantageous for scenarios involving overhead vents, ductwork inspections, or examining high-power transmission towers that are located far away. The telephoto lens provides the means to carry out these tasks safely from ground level.

A notable advantage is that, rather than necessitating multiple distinct cameras for each task, cost-effective "smart" add-on lenses can be employed across several compatible cameras. These lenses eliminate the need for special recalibration for each camera, enabling quick and efficient lens swaps during the course of a job. This approach offers a cost-effective and versatile solution to cover a range of inspection needs without the burden of multiple camera setups.

4. Macro Lens

Embrace a focus on intricacy and fine details by considering the utilization of a macro lens. These specialized lenses excel in capturing minute particulars at close distances, rendering them particularly valuable for examining small-scale objects such as electronic circuit components and chips. When dealing with components that dissipate heat, a macro thermal camera lens crafted from germanium can offer unparalleled clarity, making even the tiniest details distinctly visible.

In summary, choosing a good quality germanium glass and its field-of-view angle operation are crucial for optimizing the performance of thermal surveillance systems so as to capture quality detections of temperature variations effectively.