The recent incident involving a dust explosion at an industrial building in Tuas, which tragically resulted in the loss of three workers' lives, serves as a stark reminder to industries that handle highly combustible dust and particles. Various sectors, including food processing, chemical manufacturing, rubber and plastic production, woodworking, and metalworking, generate dust particles, ranging from sawdust and metal particles to organic powders like flour and starch.

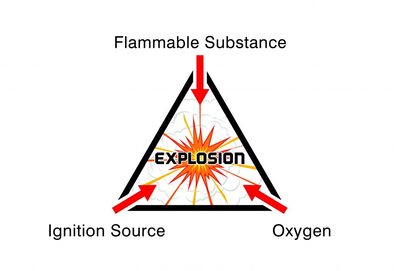

When these airborne dust particles reach a critical concentration in combination with sufficient oxygen and an ignition source, the potential for a dust explosion or fire becomes a real concern. Consequently, it becomes imperative to implement effective dust control measures within workplaces to mitigate the risk of dust-related incidents.

Several recommended strategies to manage the risk of dust explosions include:

- Installing localized exhaust ventilation (LEV) systems to capture and contain dust particles.

- Employing equipment that is flame-proof or tools that do not generate sparks when dealing with combustible powders.

- Incorporating explosion relief vents within units where powders are handled.

- Implementing physical segregation between areas that handle combustible dust and other workspaces.

- Maintaining rigorous housekeeping practices to prevent the accumulation of dust.

- Educating employees about the hazards posed by combustible dust and promoting safe handling protocols.

Companies are also urged to assume greater responsibility for workplace safety and health (WSH). This could involve the establishment of comprehensive monitoring systems to track WSH performance, including the introduction of a reporting system for near-miss incidents to encourage timely reporting by employees.

In turn, workers are advised to promptly and accurately report incidents and to treat WSH initiatives with the utmost seriousness.

Refer to the Ministry of Manpower (MOM)’s Circular on the Hazards and Controls of Combustible Dusts for more information.