Eliminating Risks with Fire and Gas Detection

FGS detection and mitigation is a safeguard against unacceptable fire and explosion risk. FGS actively identifies the release of flammable materials and mitigates the consequences by various means, including:

- Active Alarms

- Water Spray Fire

- Explosion Deluge

- Emergency Shutdown System (ESD)

- Ignition Source Isolation

An FGS that has been properly designed will not prevent a hazardous consequence from occurring; however, it can reduce the likelihood of a small leak escalating into a much larger consequence that could damage equipment or fatally injure personnel.

Fire and Gas Detection Systems (FGS) are critical components for the overall safety and operation of any facility and its personnel. Using dedicated field devices, FGS detection continuously monitors heat, smoke, temperature and toxic or combustible gas levels.

Furthermore, it is included under the Occupational Safety and Health Administration (OSHA) provisions with the intent to minimize the catastrophic consequences of toxic, reactive or explosive chemicals.

Three Ways to Determine FGS Effectiveness

There are three factors that determine the overall performance of an FGS, as measured by the risk reduction it provides.

1. Detection Performance:

An inadequate detection rate has the potential to restrict the overall efficiency of a system. According to research conducted by the Health and Safety Executive (HSE), which analyzed eight years of data regarding hydrocarbon releases, the rate of effective detection stood at a mere 60%. Furthermore, the identification of numerous releases suffered from delays, enabling flammable clouds to expand and the resulting consequences to escalate. This underscores the point that even with dependable mitigation systems in place, achieving satisfactory risk reduction is contingent upon maintaining extensive detector coverage. When it comes to functions like FGS (Fire and Gas System), the evaluation of detector coverage should receive comparable, if not heightened, quantitative scrutiny similar to assessing the average probability of failure on demand for the hardware design.

2. Mitigation System's Availability:

This is the probability that the system will perform as designed. The International Society of Automation (ISA) framework (ANSI/ISA-61511-1-2018 / IEC 61511-1:2016) gives requirements for the specification, design, installation, operation and maintenance of a Safety Instrumented System (SIS) and calls for the allocation of safety functions to determine the Safety Integrity Level (SIL). For an FGS, an SIS is used to implement one or more safety functions, composed of any combination of gas and fire sensors, logic solvers and final elements such as isolation valves, water spray, etc.

3. Evaluation of the Mitigation System's Efficacy:

Typically, this can be ascertained through analysis, utilizing tools like a competent fluid dynamics software package. It's crucial for the water spray systems to be meticulously designed to significantly diminish the outcomes of fire or explosion occurrences. Similarly, evacuation alarms must possess sufficient audibility for individuals in inhabited structures.

The Benefits of the Performance-Based Approach

Several FGS designs are based on prescriptive methods, experience or rules of thumb. These approaches are less than ideal since they fail to quantify the true risk reduction of FGS designs. A better design method is a performance-based approach, as described in the comprehensive framework ISA TR 84.00.07-2018.

This approach is "intended for use in evaluating the effectiveness of fire and gas systems in process industry applications. It addresses the implementation of FGSs to reduce the risk of hazardous releases involving safety impact.”

Two Ways Detector Coverage Can Be Quantified

There are two methods for determining detector coverage: Geographic and Scenario-based.

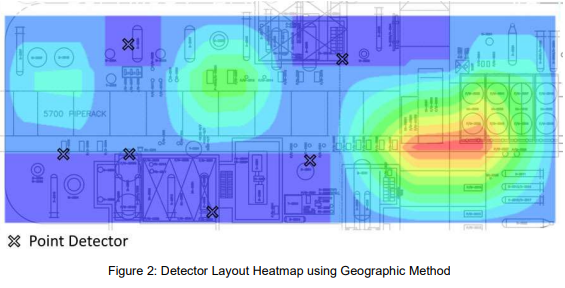

1. Geographic Coverage

Geographic coverage starts by locating a design bases' fire or gas cloud size in the area of concern and measuring what fraction of positions are detected by the current layout. This is the smallest allowable hazard that if detected results in the desired level of risk reduction. (For a flammable release, it may be the gas cloud size that can cause unacceptable occupied building damage.)

It is important to note that while a smaller design basis hazard will have a higher risk reduction, it will also require more detectors to meet the necessary detection coverage rate.

The result is an overall detector coverage fraction and a heat map showing which areas have the highest rates of non-detection and are good candidates for additional detectors.

2. Scenario-based Coverage

Scenario-based Coverage rates a model's discrete leak scenarios at equipment locations using a leak size capable of producing a design basis consequence. Each scenario is released in multiple directions and a successful detection by the network is assessed. The final detection coverage rate is the ratio of detected leak scenario cases divided by the total leak scenario cases.

Scenario-based coverage allows for more targeted detector placement near the hazard source and can include the influence of site-specific equipment and geometry on the dispersion or fire spread. However, a downside is that it requires more consequence modeling to ensure all leak sources are accounted for in an area.

Conclusion

In conclusion, it is important to evaluate your FGS function using a performance-based approach via facility siting, consequence, frequency and risk modeling, which allow you to understand to map out your existing or proposed detector layout coverage factor. This will give you clearer assessment and mitigation availability and effectiveness using such modeling capabilities.