OVERVIEW

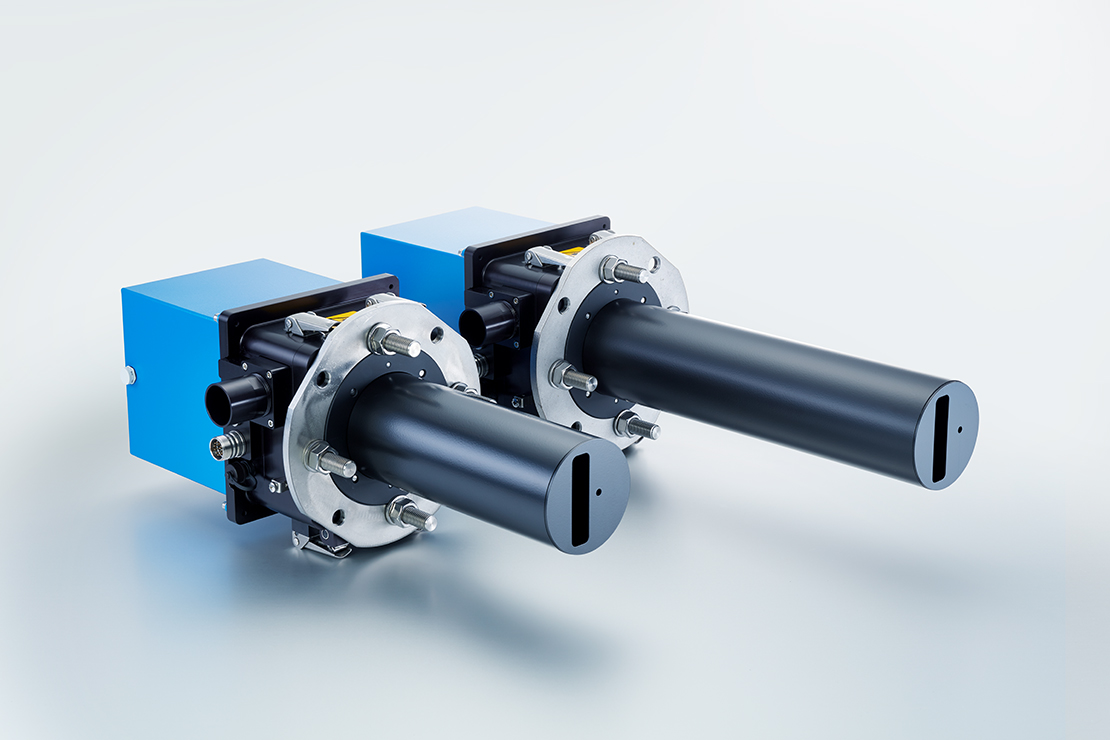

D-R 320

DUST MONITOR

For continuous, contactless measurement of low to medium dust concentrations in dry flue and process gases. Also suitable for corrosive gases and potentially explosive atmospheres.

- Continuous dust measurement

- Smallest certified measuring range 0 … 7.5 mg/m3

- Single-sided installation without optical alignment

- Automatic control functions

- Continuous, integrated purge air monitoring and control

- Maintenance and linearity check without disassembly

- Contactless measurement

- Suitable for official emission monitoring

- Reliable measurement of small dust concentrations

- Space-saving and easy installation

- Long life time and high availability under extreme plant conditions

- Low maintenance

- Emission measurement of dry flue gases at the stack

- Temperatures up to 600 °C

- Corrosive flue gases, plants with complex gas matrix

- Measurement of dry process gases with small concentrations

| Measuring principle | Backward scattering, single-sided installation, contactless and in-situ measurement |

| Measuring variable | Stray light units, calibratable as dust concentration in mg/m³ |

| Measuring range | Minimum 0 … 5 mg/m³ Maximum 0 … 200 mg/m³ |

| Certified measuring range | 0 … 7.5 mg/m³ |

| Ambient conditions | Installation location: Indoor or outdoor installation** Temperature: -40 … +60 °C -30 … +60 °C (ATEX) -20 … +60 °C (IECEx) |

| Operating conditions in duct | Temperature: Maximum 600 °C Relative humidity: 0 … 95%, non-condensing Relative pressure: -50 … +50 hPa -50 … 0 hPa (ATEX/IECEx) |

| Duct dimensions | Minimum inner diameter: 0.7 m Maximum wall thickness: 0.56 m |

| Interface* | Analogue output: 1x 4 … 20 mA, maximum 400 Ohm, potential-free (various parameters adjustable) Digital output: 2x NC/NO, maximum 60 VDC, 30 VAC), 0.5 A (various parameters adjustable) RS 485 Modbus RTU, USB Status display: LED |

| Operation and display | Software D-ESI 100*** or Operating unit D-ISC 100 |

| Control functions | Automatic zero point and reference point measurement, automatic contamination measurement and compensation, integrated purge air monitoring and control |

| Protective functions | Integrated fail-safe shutter (optional) |

| Light source | Laser, class II, < 1 mW at 650 nm |

* Additional interfaces with D-ISC 100 operating unit

** Weather protection cover required for outdoor installation

*** Enables remote access via web interface, PC with Windows operating system required

DURAG Group products and solutions under its group such as:

- SMITSVONK (Netherlands-based) for high-energy ignition systems, pilot burners, and ignition burners

- Hegwein GmbH (Stuttgart-based) for (gas and oil ignition burners and gas burners

- AP2E (France-based) for ProCeas® lasercem analyzers for gas traces in hydrocarbons via infrared spectrometry online gas analysis, with no need for sample conditioning/heating

- Grimm Aerosol Technik for detection and analysis of aerosol particles in various fields such as environmental monitoring, occupational safety and research.

- Mercury Analysers for measuring principle that allows separate determination of elemental and oxidized mercury

- Dust Monitors and Analysers for measure dust concentrations in dry and wet gases continuously

Approvals And Certifications

- TÜV certificate (Germany requirement for continuous emission monitoring systems)

- Compliant to US EPA, QAL 1 Certification, EN 14181, EN 15267, EN 16911-2

- FM approval (ANSI safety standards)

- Explosion Proof Certification (IECEx, ATEX, NEPSI, TIIS)

- CE Marking (conforms with the applicable EU directive)

The DURAG GROUP is a leading provider of intelligent solutions for combustion technology, emissions and ambient air monitoring, multi-gas analysis, tunnel sensors, and environmental and process data management, with more than 70 years of experience.

The company has around 500 specialists who offer modern technology, certified instruments, and reliable services for the individual requirements of customers worldwide.

It provides a comprehensive product portfolio for industrial combustion and flame control technology, visualization and online analysis of thermal processes, gas analysis, as well as the measurement and analysis of emissions and ambient air monitoring.

D-R 320