OVERVIEW

D-VTA 200 FOR CRACKING FURNACES

VIDEO AND THERMOGRAPHY SYSTEM

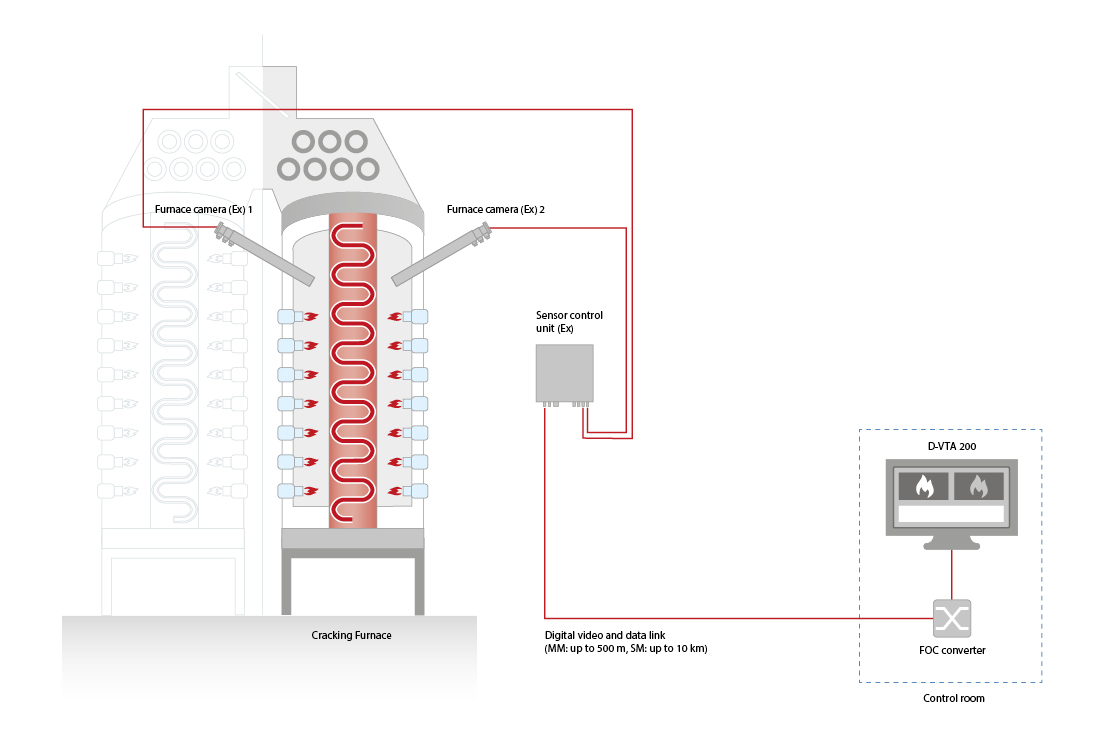

Video and thermography systems for cracking furnaces are used in the petrochemical industry to monitor the furnace interior and production tubes. Special combustion chamber cameras are used for hazardous areas. The systems help to detect burner anomalies and combustion imbalances, reducing the risk of tube ruptures and unnecessary shutdowns.

- Brilliant 24/7 live videos and temperature distribution from the cracking furnace

- Special furnace camera (D-FS 50… Ex) with sensor control unit (D-SCU… Ex) for use in hazardous areas

- Detection of imbalances and anomalies in individual burners

- Visualization of the individual burner flames during the start-up process

- Early detection of hotspots on the process tubes

- Cost reduction by avoiding tube ruptures: balanced heat input to the tubes, e.g. same on right and left

- Less downtime through early detection of combustion problems such as missing ignition or disruption of the gas or air supply to an individual burner

- Reduction of wear and tear on the wall lining by avoiding partial overheating

| Brief product description | Systems with fixed installation, for hazardous areas Water or air cooled systems 2 or 4 furnace cameras in one system |

| Sichtwinkel | Wide angle: 90°, 72°, 54° (diagonal, horizontal, vertical) Standard: 60°, 48°, 36° (diagonal, horizontal, vertical) Zoom: 30°, 24°, 18° (diagonal, horizontal, vertical) |

| D-SCU 5xEx | |

| Power supply | 100 ... 240 VAC, 50 ... 60 Hz |

| Ambient temperature | -10 ... 55°C |

| Degree of protection | IP 66 |

| Explosion protection | II 2GD Ex d IIC T5 Gb Ex tb IIIC T100°C Db |

| D-FS 50 … Ex | |

| Video resolution | 1,280 x 960 Pixel |

| Power supply | 12 VDC |

| Degree of protection | IP 66 |

| Explosion protection | II 3G Ex pzc IIC T4 GcII 3D Ex pD IIIC T130°C Dc |

DURAG Group products and solutions under its group such as:

- SMITSVONK (Netherlands-based) for high-energy ignition systems, pilot burners, and ignition burners

- Hegwein GmbH (Stuttgart-based) for (gas and oil ignition burners and gas burners

- AP2E (France-based) for ProCeas® lasercem analyzers for gas traces in hydrocarbons via infrared spectrometry online gas analysis, with no need for sample conditioning/heating

- Grimm Aerosol Technik for detection and analysis of aerosol particles in various fields such as environmental monitoring, occupational safety and research.

- Mercury Analysers for measuring principle that allows separate determination of elemental and oxidized mercury

- Dust Monitors and Analysers for measure dust concentrations in dry and wet gases continuously

Approvals And Certifications

- TÜV certificate (Germany requirement for continuous emission monitoring systems)

- Compliant to US EPA, QAL 1 Certification, EN 14181, EN 15267, EN 16911-2

- FM approval (ANSI safety standards)

- Explosion Proof Certification (IECEx, ATEX, NEPSI, TIIS)

- CE Marking (conforms with the applicable EU directive)

The DURAG GROUP is a leading provider of intelligent solutions for combustion technology, emissions and ambient air monitoring, multi-gas analysis, tunnel sensors, and environmental and process data management, with more than 70 years of experience.

The company has around 500 specialists who offer modern technology, certified instruments, and reliable services for the individual requirements of customers worldwide.

It provides a comprehensive product portfolio for industrial combustion and flame control technology, visualization and online analysis of thermal processes, gas analysis, as well as the measurement and analysis of emissions and ambient air monitoring.

D-VTA 200